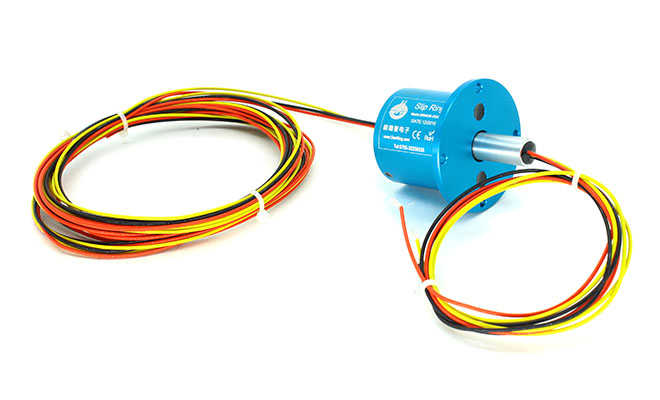

High Temperature Slip Ring

SENRING Y series high temperature thermocouple slip rings, key materials are imported from Germany and Japan,applied to transmit power and thermocouple signal when 360° rotating, can work stably in 100~250℃ high temperature working conditions such as hot roller, heating equipments... ,Long time practice applications convince its execellent trasmitting performace and reliable quality.

Product Manual Installation @Technical InquiryFeatures

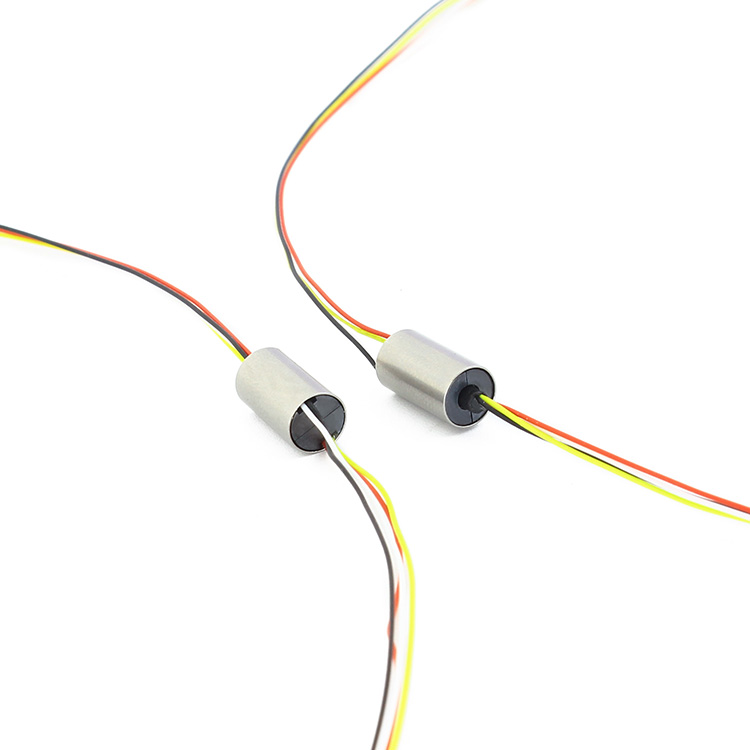

- ● can work stably in 100~250℃ high temperature working conditions;

- ● Can transmit various thermometry signals of PT100 and K type thermocouple,the accuracy of thermometry is less than 0.1℃;

- ● military super hard gold plating treatment for contact points make sure low electrical noise and long working life;

- ● Advantages: low torque, low loss, low electrical noise, no maintenance,etc.

Part No. Description

| Y | - | ID OD | - | power circuits | - | signal circuits | - | working temp. |

1056:ID 10mm,OD 56mm

2086:ID 20mm,OD 86mm

3099:ID 30mm,OD 99mm

4099:ID 40mm,OD 99mm

50119:ID 50mm,OD 119mm

60130:ID 50mm,OD 119mm

70140:ID 70mm,OD 140mm

80158:ID 80mm,OD 158mm

100185:ID 100mm,OD 185mm

0210: 2 wires 10A

0620: 6 wires 20A

0830: 8 wires 30A

02S: 2 wires 2A signal

06S: 6 wires 2A signal

120:120℃

250:250℃

For example

● "Y1056-06S-200": Y1056 means high temperature thermocouple slip ring (hole size 10mm,OD 56MM),06S means 6 circuits signal(thermocouple signal optional),200 means working temperature 200℃;

● "Y3099-0210-02S-250": Y3099 means high temperature thermocouple slip ring (hole size 30mm.OD 99mm),0210 means 2 circuits signal(thermocouple signal optional),250 means working temperature 250℃.

model list

| Model | ID | OD | length L | Pls refer to below table according Spec Code marked on above drawing | |||||

| A | B | C | E | F | M | ||||

| Y1056 | 10 | 56 | 21.2+ rings no. *2.8 | 6 | 6 | 12 | 68 | 3 | M3 |

| Y2086 | 20 | 86 | 24+ rings no. *4 | 8.5 | 9.5 | 19.5 | 110 | 4 | M4 |

| Y3099 | 30 | 99 | 24+ rings no. *4 | 8.5 | 9.5 | 19.5 | 122 | 4 | M4 |

| Y4099 | 40 | 99 | 24+ rings no. *4 | 8.5 | 9.5 | 19.5 | 122 | 4 | M4 |

| Y50120 | 50 | 120 | 28+ rings no. *4 | 8.5 | 9.5 | 19.5 | 144 | 4 | M4 |

| Y60130 | 60 | 130 | 28+ rings no. *4 | 9 | 9.5 | 19.5 | 156 | 4 | M4 |

| Y70140 | 70 | 140 | 34+ rings no. *4 | 9 | 9.5 | 19.5 | 160 | 4 | M4 |

| Y80158 | 80 | 158 | 34+ rings no. *4 | 12 | 12 | 26 | 192 | 5 | M6 |

| Y100185 | 100 | 185 | 40+ rings no. *4 | 12 | 12 | 26 | 218 | 5 | M6 |

| Y120215 | 120 | 215 | 48+ rings no. *4 | 15 | 12 | 26 | 248 | 5 | M6 |

| Y150248 | 150 | 248 | 56+ rings no. *5 | 16 | 12 | 26 | 280 | 5 | M8 |

| Y180298 | 180 | 298 | 60+ rings no. *5 | 16 | 15 | 35 | 332 | 6 | M8 |

| Y200320 | 200 | 320 | 60+ rings no. *5 | 16 | 15 | 35 | 350 | 6 | M8 |

| Y250396 | 250 | 396 | 78+ rings no. *5 | 16 | 15 | 35 | 420 | 6 | M8 |

| Y300430 | 430 | 300 | 96+ rings no. *6 | 25 | 15 | 35 | 464 | 6 | M12 |

"rings no." explanation: each 2A/5A signal circuit as 1 ring ,N signal circuits as N*1 rings; each PT100 channel as 3 rings, each K type thermocouple as 2 rings; each 10A circuit as 1 ring, each 20A circuit as 2 rings, each 30A circuit as 3 rings ,and so on.

For example :2 circuits signal as 2 rings,2 circuits 10A current as 2 rings,1 circuit 20A as 2 rings,2 circuits 20A as 4 rings,1 circuit 30A current as 3 rings,2 circuits 30A as 6 rings.

Technical Specification of the slip ring

| Mechanical Data | Electrical Data | |||

| spec | data | spec | data | |

| working life | 80 millions for ref(depends on working conditions) | power | signal | |

| Rotating speed | 250RPM | voltage range | 0∼690VAC/VDC | 0∼440VAC/VDC |

| working temp. | -30℃∼80℃ | insulation resistance | ≥1000MΩ/500VDC | ≥1000MΩ/500VDC |

| work humidity | 0~85%RH | lead wire spec. | AWG17# Silver-plated teflon | AWG22# Silver-plated teflon |

| contact material | precious metal:gold-gold | lead wire length | standard 150mm(can be customized) | |

| torque | 0.1N.m;+0.03N.m/6路 | Electrical noise | < 0.01Ω | |

| CE certificate | Yes | |||

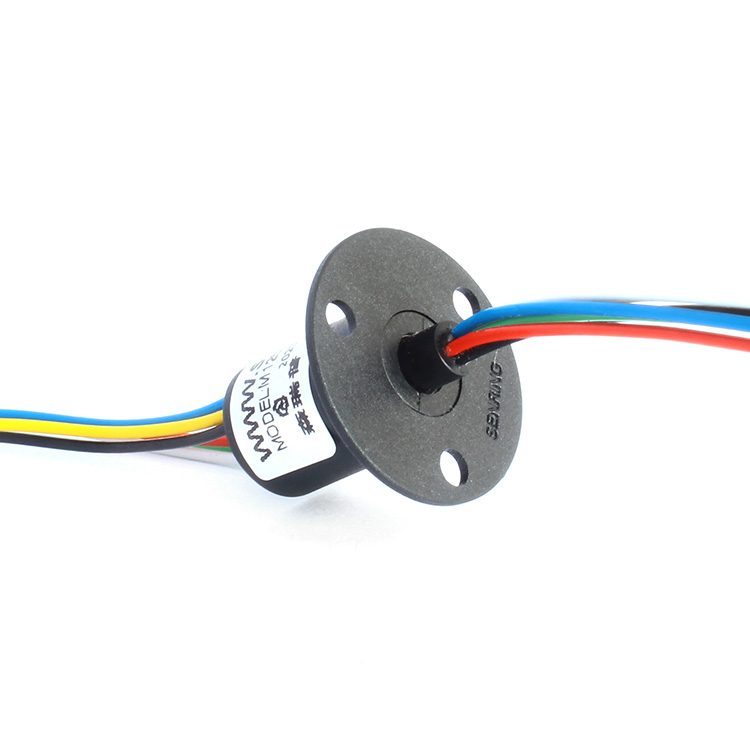

Color code of Lead Wire

| ring no. | color | ring no. | color |

| 1 | black | 13 | WHT/BLK |

| 2 | brown | 14 | WHT/BRN |

| 3 | red | 15 | WHT/RED |

| 4 | orange | 16 | WHT/ORG |

| 5 | yellow | 17 | WHT/YEL |

| 6 | green | 18 | WHT/GRN |

| 7 | blue | 19 | WHT/BLU |

| 8 | purple | 20 | WHT/PUR |

| 9 | grey | 21 | WHT/GRY |

| 10 | white | 22 | BLK/RED |

| 11 | pink | 23 | BLK/BRN |

| 12 | lightblue | 24 | transparent |

Applied projects

How to improve the working life and stability of dry mechanical products by using SenRing high temperature slip ring.SENRING ELECTRONICS

Searching for a High-Quality Slip Ring or Rotary Union to Fit Your Application?

Look no further—just leave us a message, and we’ll provide you with all the information you may need.

Send a MessageIn-House Production

All the slip rings and rotary unions by Senring are built with our own factory and R&D center. We do not outsource orders.

Simple Integration

Our products are robust enough to be used in the different application, yet compact meaning you can use them for any design.

Live Tech Support

Our specialists are ready to assist you whenever you need it. We also provide detailed Doc & video instructions.

Long Warranty and Service

All come with one-year warranty, and service life estimates up to 45K hours. All comply with best industry practices.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE