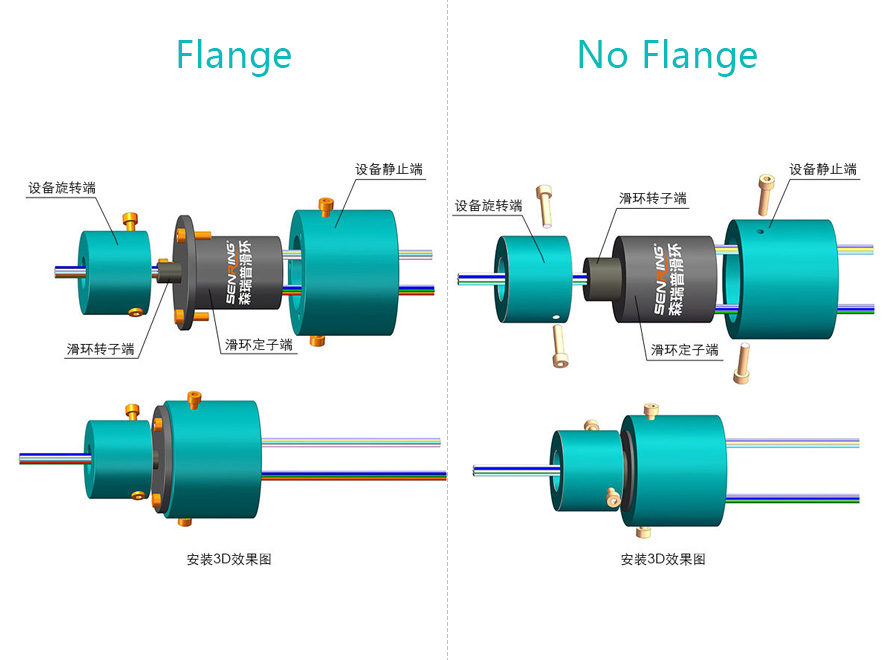

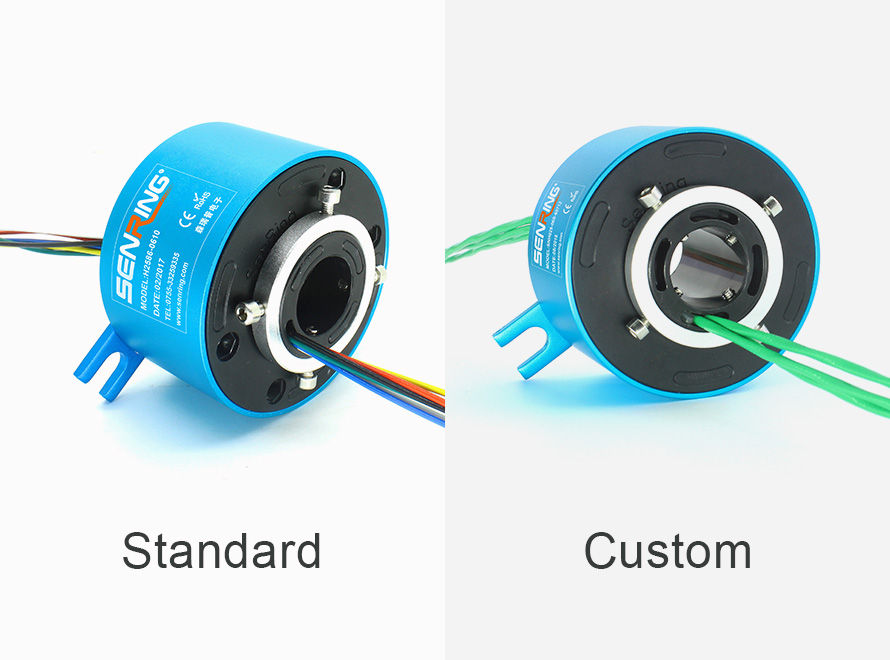

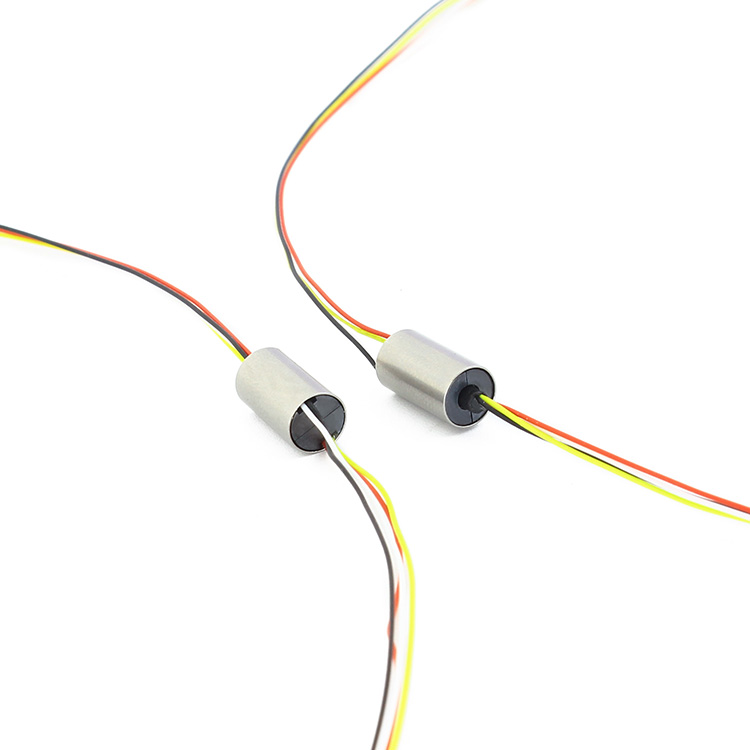

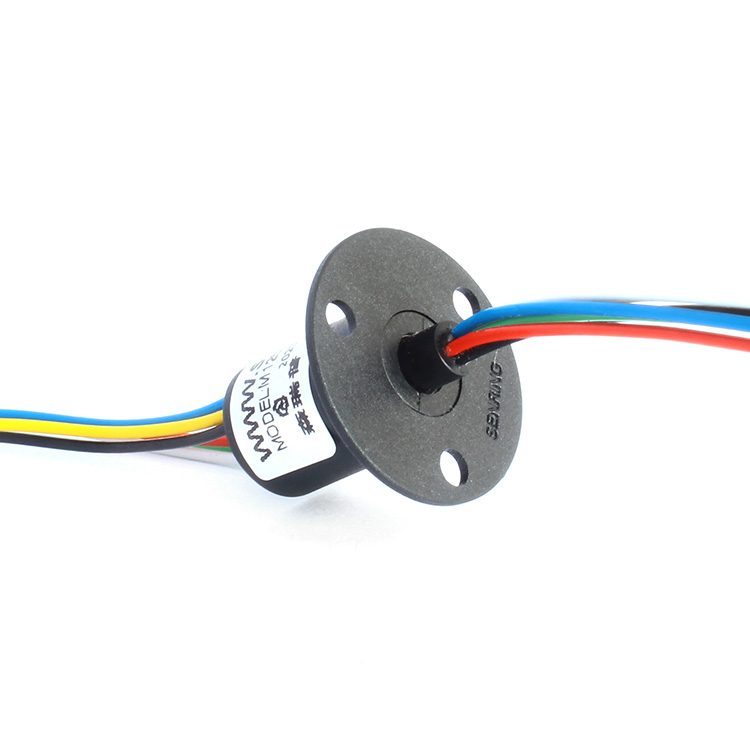

The function of Senring conductive slip ring is to conduct electricity and transmit kinds of signals when the device 360° rotating. Of course, you can customize and combine with the mudiems of pneumatic and liquid. The same products and workmanship, why some can be used for a long time but some not? Is that because the quality of slip rings is poor or the slip rings are not be used according to the requirements?

Lately I met a domestic client, the slip ring model he purchased was SNH038-0610-02S. The problem he encountered was that the slip ring was burned out when it was used firstly. Through communication, Senring's engineer found out the reason. That is because his wrong using method, he didn't connect the wires according to the demands. In fact, this slip ring can only be used for transmitting 6circuits@10A current and 2circuits@2A signal, but this customer use the signal channel to transmit the 20A large current directly. He could have paralleled 2circuits @10A thereof to through 20A large current, as a reasult, he made the transmission through 2circuits@10A. Because these two channels are used for transmitting signals, in the end, the slip ring was burned out.

Here is the suggestion, when you choose a slip ring, you need to tell the parameters of your products to the salesmen of Senring, especially the biggest current. Then, you need to use the slip ring strictly according to the design parameters of slip ring. As long as you use the slip ring according to the specs, it will be ok to use the slip ring for a few years.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE