How to choose contact materials of slip rings

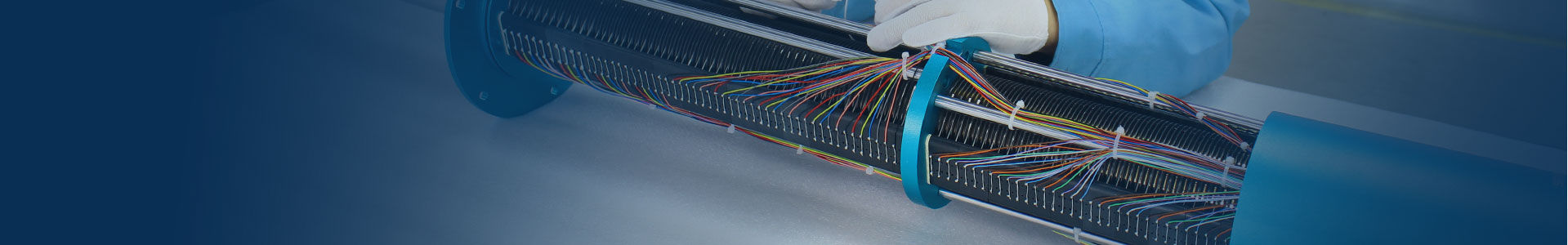

With the progress of science and technology, the world has become an era dominated by intelligent production.Conductive slip ring has not only has the conductive function, as the product improvement and technology progress, Senring slip ring can transmit 1000M Ethernet, USB, VGA, HDMI, optical fiber and other signals, also can be combined to through pneumatic, hydraulic, compressed air, steam and other medias.

Sering slip ring can transmit kinds of signals from static equipment to rotary equipment, its main technology including: contact resistance, insolution performance and anti-disturbance performance./

If the contact resistance of the conductive slip ring is large, the temperature at the contact point will be increased when the current passes through, and it may even cause the welding of the brush silk and the slip ring. At the meantime, the increasing of contact current will affect the transmission of information, so the smaller the contact resistance, the better. The contact materials, contact form and contact pressure are the causes of contact resistance./

There are many options on material choosing of brush silk. Just take copper silk as the example. Copper silk is divided into red copper silk, brass silk, copper silk, bronze silk, phosphorous copper silk, etc. With different function, the slip ring with different model adopts different brush silk. Some small-scale factories improve their competetitiveness through reducing the price of slip rings, so the copper silk they used mostly is common copper silk. The biggest disadvantages of this slip ring is short working life, unstable transmission signal.

Product quality is the survival and development foundation of enterprise. Senring high-quality slip rings mostly adopt beryllium bronze, gold nickel wire and other high-end copper wire. This kind of brush wire not only can satisfy good conduction performance, but have better anticorrosive action. However, the price is expensive. Sometimes, some customers who buy in bulk don't have high requirement to the slip ring. They hope the price to be cheaper. In orde to reduce price and guarantee the quality of slip ring, brass is also a better choice. Brass has a high conductivity, good thermal conductivity, high melting point, low resistance temperature coefficient; It has the characteristics of anti - oxidation, anti - vulcanization, anti - corrosive gas, etc. and have certain hardness, good wear resistance and so on; Besides, good resistance to welding, arc corrosion and burn.

Mentioned above is the introduction to brush silk of conductive slip ring. If you want to mix a variety of video signals, or other signals such as optical fiber or USB, you need to use special process and special material.

- Why does SenRing slip rings have better quality? Technology comparison between SenRing and other ma

-

- 26-12-2014

- With good reputation in the whole slip ring industry, SenRing has advantages whatever from materials, assembly technology or product performance.Why does SenRin

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE