The maintance of slip ring and slip ring brush

In daily inspection and reparation in industrial generator set, the part of rotator and brush is easily to get some problems, and it is strong related with daily maintenance, so more details should be noticed in routine use. For some big generator, it is vital important to inspect slip rings periodically, because it is related with normal operation, operating efficiency and work safety.

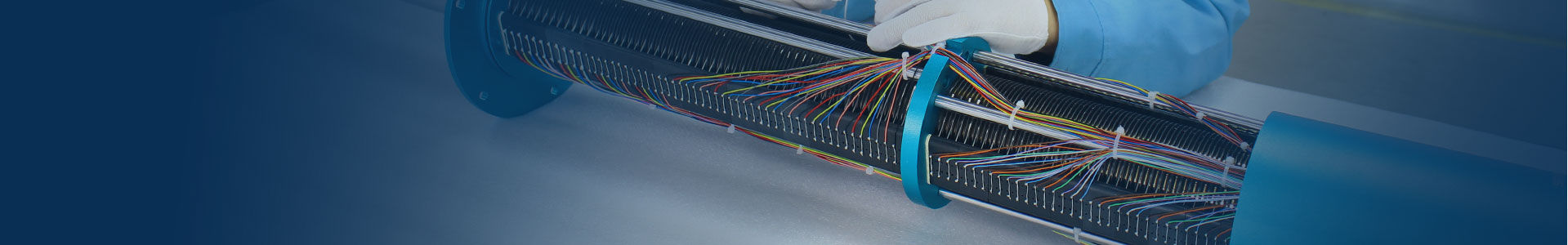

through hole slip ring

Most of electric enterprises have one inspection per year, and around 5-8 years have a major maintenance. Long running status will amass plenty of faults, what`s more, it is easy to emerge some problems in the part of brush, according to our own rich experiences and strategies of some years of time, the slip ring brush must be inspected by insulating property, if their performance of insulation resistance and AC volts are degreed it means insulating property already have some hazards, it is leaded by dusts by friction of brush and corrosion of oil leak. The destructive effect cannot eliminate.

The maintenance of brush of slip ring, as for general electric enterprises choose advanced constant voltage brush, it will be exclusive of stressful from spring. But when spring lose elastic force, it will lead to bad contact and even damage the surface of slip ring as spark phenomenon, so it is necessary to take slip ring`s phenomenon of fatigue into consideration during the process of examine and repair.

The working temperature of slip ring around 50, if exceed this temperature, the component will be damaged, so workers should inspect internal structure periodically (is it smooth when rotary or is it clear in insulate parts), only stress details can eliminate defaults.

- Working principle and structure chart of Senring carbon brush-slip ring principle

-

- 21-02-2017

- Electric brush slip ring of Senring is dominated, carbon brush slip ring is auxiliary.Carbon brush slip ring is used widely before electric brush slip appears.

- more+

- What are the two functions of industrial bus slip sings and brushes?

-

- 08-03-2024

- he two functions of slip rings and brushes are to provide electrical power to the rotor and to transmit electrical signals from the rotor to the external circui

- more+

- What is the difference between through hole Slip Ring and carbon brushes?

-

- 13-03-2024

- Through-hole slip rings and carbon brushes are both components used in electrical systems, particularly in rotating machinery, to transfer electrical signals or

- more+

- Why do we use carbon brushes in high speed slip ring motor?

-

- 22-01-2024

- Carbon brushes are used in slip ring motors because they provide a reliable and efficient electrical connection between the rotating part of the motor (the roto

- more+

- The maintance of slip ring and slip ring brush

-

- 30-10-2010

- In daily inspection and reparation in industrial generator set, the part of rotator and brush is easily to get some problems, and it is strong related with dail

- more+

- Importance of brush silk of Sering electric brush slip ring and how to choose the

-

- 24-02-2017

- Senring slip ring is divided into mercury slip ring, electric brush slip ring, fiber optial slip ring, etc. Different slip ring's structure and signal has d

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE