How do you know if a through bore slip ring is bad?

Determining whether a through bore slip ring is faulty involves inspecting various aspects of its performance and physical condition. Here are several indicators that can help identify a potentially bad through bore slip ring:Electrical Testing: Use a multimeter or other appropriate testing equipment to check for continuity and electrical integrity across the slip ring. An open circuit, inconsistent resistance, or irregular voltage readings could indicate an electrical fault.

Signal Quality: If the slip ring carries data or signals, monitor the output for any degradation, noise, or loss of signal quality. This could indicate wear, contamination, or damage affecting the conductive pathways.

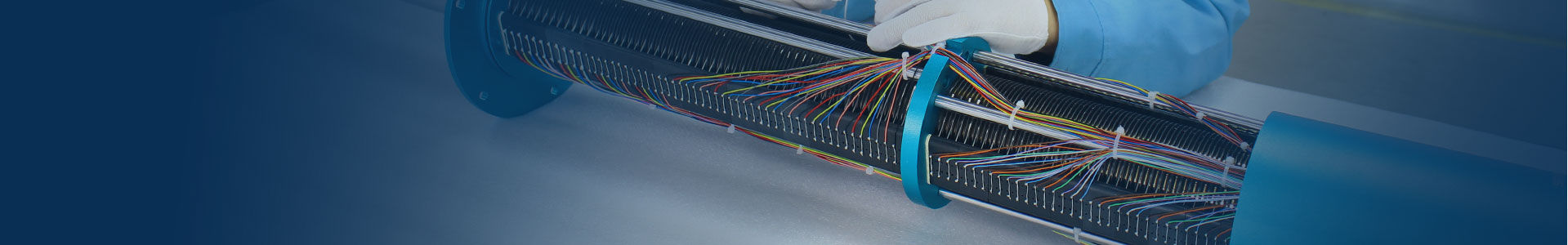

Visual Inspection: Check for physical signs of damage, such as worn brushes, pitting on the rings, or evidence of arcing. Any visible damage, debris, or irregularities may suggest a problem with the slip ring.

Temperature Monitoring: Overheating can be a sign of excessive friction or poor electrical contact within the slip ring assembly. Monitoring temperature during operation can provide insights into potential issues.

Vibration and Noise: Unusual vibration or noise during slip ring operation may indicate mechanical wear, misalignment, or damage to the internal components.

Maintenance Records: Reviewing maintenance records and service history can offer valuable insights into the slip ring's condition and any past issues that may have arisen.

Performance Testing: Compare the slip ring's current performance against its original specifications. Any deviation from expected performance parameters could indicate a problem.

Application Issues: Consider any operational challenges or anomalies in the system that the slip ring is a part of. If there are unexplained electrical or signal-related issues, the slip ring could be a potential source of the problem.

If any of these signs are observed, it's important to further investigate the slip ring, potentially disassembling and inspecting its components, consulting with a qualified technician, or considering a replacement if necessary. Regular maintenance and periodic inspections can help prevent unexpected failures and ensure the reliable performance of through bore slip rings.

For more details on miniature through bore slip rings products, please view :https://www.senring.com/through-hole-slip-ring/medium-hole/h3099.html

FAQ questions:

1.Do miniature through hole slip rings rotate with the coil?

2.How does an electrical optic slip ring work?

3.What is the current rating of a high current slip ring?

4.What is the difference between through hole Slip Ring and carbon brushes?

5.Are thorugh hole slip rings usually made of copper?

- How do you know if a through bore slip ring is bad?

-

- 27-03-2024

- Determining whether a through bore slip ring is faulty involves inspecting various aspects of its performance and physical condition. Here are several indicator

- more+

- What is the use of through bore slip ring?

-

- 27-12-2023

- A through bore slip ring is used to transmit power or signals between two rotating components in a machine, such as a motor or generator. The slip ring is desig

- more+

- What is the use of through bore slip ring?

-

- 22-04-2024

- The through bore slip ring is used for holding the work piece and transmitting torque from the machine spindle to the work piece. The through bore allows coolan

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE