What are the two functions of industrial bus slip sings and brushes?

he two functions of slip rings and brushes are to provide electrical power to the rotor and to transmit electrical signals from the rotor to the external circuit.Slip rings and brushes serve two primary functions in electrical systems, particularly in rotating machinery and equipment. These functions are essential for maintaining continuous electrical connectivity across rotating interfaces and enabling the transmission of power, signals, or data without the hindrance of fixed wiring.

Functions of Slip Rings:

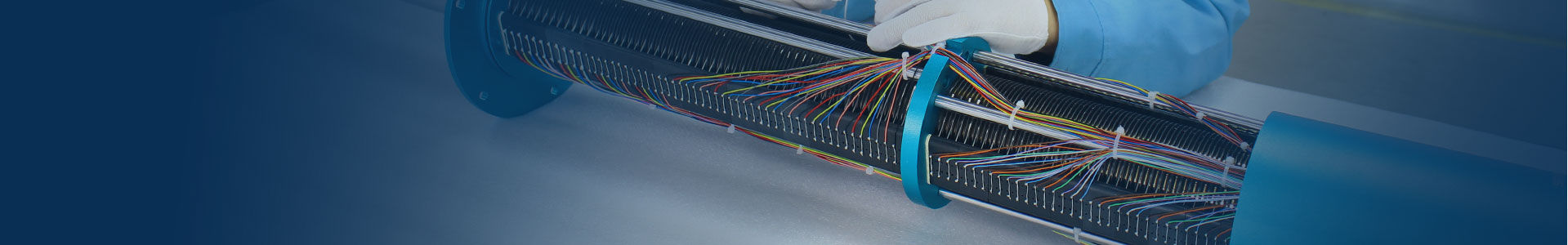

Continuous Electrical Connection: The primary function of slip rings is to provide a continuous electrical connection between stationary and rotating components. They enable the transfer of electrical power, signals, or data from a stationary source to the rotating equipment and vice versa, allowing for seamless operation without the constraints of fixed cabling.

Allow Unrestricted Rotation: Slip rings facilitate unrestricted rotation by transmitting electrical signals and power across rotating interfaces. This capability is crucial in applications where continuous rotation is required, such as in wind turbines, radar systems, rotary tables, and cranes, among others.

Functions of Brushes (Carbon or Metal):

Maintain Contact with Slip Rings: Brushes play a critical role in establishing and maintaining contact with the conductive rings of a slip ring assembly. Whether composed of carbon or metal, these brushes ensure consistent electrical connectivity between the rotating and stationary elements, facilitating efficient power and signal transmission.

Wear Compensation: In addition to maintaining contact, brushes serve to compensate for wear on the slip rings. As the slip rings rotate against the brushes, gradual wear occurs over time. The brushes help to mitigate this wear and maintain stable electrical contact by applying consistent pressure to the slip rings.

Additional Consideration:

Over time, the materials used for the brushes and slip rings must be carefully chosen to minimize wear, reduce electrical noise, and ensure long-term reliability in various operational conditions.

Summary:

Slip rings and brushes work together to enable continuous electrical connectivity and unimpeded transmission of power, signals, or data in rotating machinery. While slip rings form the conductive interface that allows electrical transfer across rotating joints, brushes play a vital role in maintaining contact with the slip rings and compensating for wear, ensuring reliable and uninterrupted electrical connections. Both components are crucial for the efficient and sustained operation of systems requiring electrical transmission across rotational interfaces.

For more details on industrical bus products, please view :https://www.senring.com/industrial-bus/

FAQ questions:

1.How does a Deublin rotary union pneumatic work?

2.What material are Industrial Bus Slip Rings made of?

3.What metal is used in through hole slip rings?

4.How do you control the speed of a slip ring motor?

5.Are thorugh hole slip rings usually made of copper?

- What are the two functions of industrial bus slip sings and brushes?

-

- 08-03-2024

- he two functions of slip rings and brushes are to provide electrical power to the rotor and to transmit electrical signals from the rotor to the external circui

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE