What metal is used in through hole slip rings?

Copper is the most common metal used in through hole slip rings.

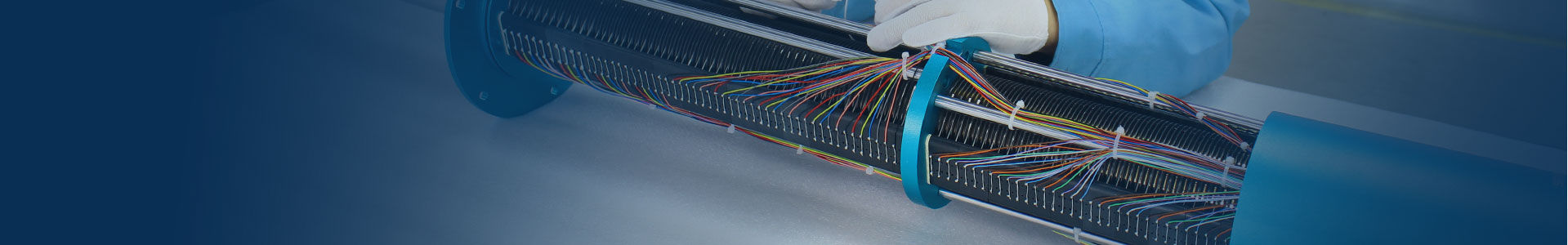

Through hole slip rings, which are used for the transmission of electrical signals and power across rotating interfaces, commonly employ various metals based on their electrical conductivity, mechanical properties, and resistance to wear. The choice of metal

is critical to ensure reliable signal transmission and minimal electrical resistance. Some of the common metals used in through hole slip rings include:

1. Gold:

Conductivity: Gold is highly conductive and exhibits low contact resistance, making it an excellent choice for slip rings where low electrical noise and stable signal transmission are crucial.

Corrosion Resistance: Gold offers exceptional corrosion resistance, ensuring long-term reliability and consistent electrical performance.

2. Silver:

Conductivity: Silver also boasts high electrical conductivity and is often used in slip rings to provide efficient signal transmission with low resistance.

Cost Consideration: While silver is an excellent conductor, its use may be limited due to cost considerations and susceptibility to tarnishing.

3. Copper:

Conductivity: Copper is widely used in electrical applications due to its high conductivity, making it suitable for slip rings that handle

significant electrical current or power transfer.

Strength and Wear Resistance: Copper's mechanical properties make it a durable choice, capable of withstanding continuous

rotational movement.

4. Precious Metal Alloys:

Combination Materials: Some slip rings may utilize precious metal alloys such as gold-palladium or silver-palladium, offering a balance between conductivity and mechanical durability.

Wear Resistance: These alloys provide improved wear resistance compared to pure gold or silver, extending the operational lifespan of the slip ring.

5. Silver-Plated Contacts:

Enhanced Conductivity: In some cases, pneumatic rotary unions may feature contacts made from other metals, such as stainless steel or brass, plated with a thin layer of silver to enhance conductivity and minimize contact resistance.

The selection of the metal for through hole slip rings depends on the specific application requirements, including the magnitude of

electrical current,

the type of signals being transmitted, environmental conditions, and the expected operational lifespan. As a result, manufacturers choose metals and coatings that optimize both electrical performance and mechanical durability to ensure reliable and long-lasting functionality in rotating electrical systems.

For more details on through hole slip rings products, please view :https://www.senring.com/through-hole-slip-ring/larger-hole/h150248.html

FAQ questions:

1.What is the difference between a rotary joint and a swivel joint?

2.What material are Industrial Bus Slip Rings made of?

3.Are thorugh hole slip rings usually made of copper?

4.How do you control the speed of a slip ring motor?

5.What is capsule slip ring and is used for?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE