Does wound rotor motor need slip ring and brushes?

Yes, wound rotor motors require slip rings and brushes as integral components of their design. These elements serve a crucial function in facilitating the operationand control of the motor. Here's a breakdown of the role of slip rings and brushes in wound rotor motors:

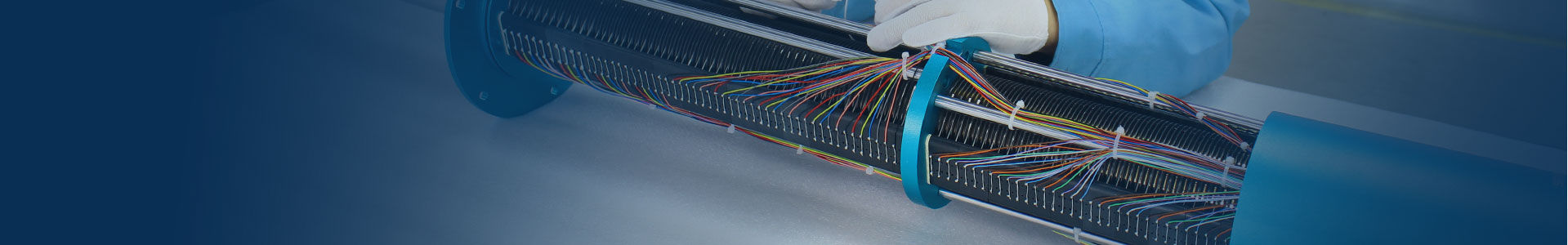

through Bore Slip Ring:

Function: through bore Slip rings in a wound rotor motor provide a means for external electrical connections to the rotor windings. They allow the transfer of power and control signals

between the stationary part of the motor (stator) and the rotating rotor assembly.

Rotor Winding Connectivity: The slip rings enable the connection of external resistors or other control devices to the rotor windings, allowing for variable speed control,

torque regulation, and adjustments to the motor's operational characteristics.

Electrical Contact: As the rotor spins, the slip rings maintain continuous electrical contact with stationary brushes, ensuring reliable transmission of electrical power and

control signals to the rotor circuitry.

Brushes:

Role: Brushes are stationary conductive components that make contact with the electrical slip ring manufacturers as they rotate, establishing an electrical connection to

the rotor windings. These brushes ensure consistent and reliable transmission of electrical power and control signals to the rotor without the need for direct wiring to the

moving rotor assembly.

Wear and Maintenance: Brushes require periodic inspection and maintenance to ensure proper contact with the slip rings, as wear over time can affect the quality of the

electrical connection. Regular maintenance helps prevent issues such as sparking, arcing, or poor conductivity that can impact the motor's performance.

Benefits of Using Slip Rings and Brushes in Wound Rotor Motors:

Variable Speed Control: The use of slip rings and brushes enables the implementation of external resistance control methods, allowing for adjustable speed and torque

characteristics in wound rotor motors.

Starting Performance: By integrating external resistors through the slip rings and brushes during motor start-up, the initial current flow and torque response can be managed,

reducing mechanical stress and enhancing starting performance.

In summary, slip rings and brushes are essential components in wound rotor motors, enabling external control and power transmission to the rotor windings, which in turn provides

the ability to regulate speed, torque, and operational characteristics, making these motors suitable for various industrial applications requiring flexible and controllable performance.

For more details on slip ring products, please view :https://www.senring.com/through-hole-slip-ring/larger-hole/h120215.html

FAQ questions:

1.Are Industrial Bus slip rings usually made of copper?

2.Why do we use carbon brushes in high speed slip ring motor?

3.What are the drawbacks of slip rings and carbon brushes?

4.What are the purpose of slp ings on rotor?

5.What is capsule slip ring and is used for?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE