What are the purpose of slp ings on rotor?

The squirrel-cage rotor is a part of the alternator that contains a rotating magnetic field. The purpose of the squirrel-cage rotor is to convert mechanical energyinto electrical energy. The squirrel-cage rotor is made up of a series of conductive bars that are connected to each other and to the rotor shaft. The bars are arranged

in a way that they form a cage around the rotor shaft. The rotor shaft is connected to the engine, and as the engine turns, the rotor shaft turns, which causes the bars

in the squirrel-cage rotor to rotate. As the bars rotate, they create a changing magnetic field, which induces an electrical current in the stator windings. This electrical

current is then used to power electrical devices in the vehicle.

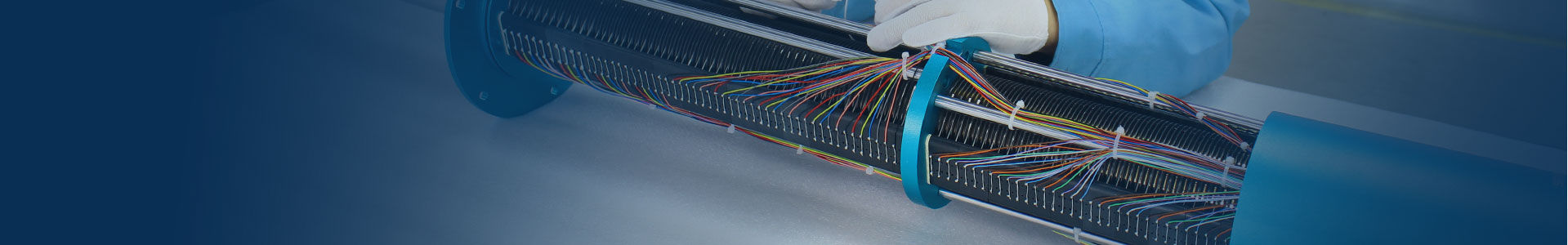

Industrial Bus Slip Rings on a rotor serve several important purposes, particularly in the context of rotating machinery or equipment. These slip rings facilitate the transfer of electrical power,

signals, data, or other electrical currents between stationary and rotating parts, enabling the seamless transmission of essential electrical connections across the rotational interface.

Here are the key purposes of slip rings on a rotor:

1. Electrical Power Transmission:

Powering Components: Slip rings enable the transfer of electrical power from stationary sources to rotating components, allowing for the continuous operation of motors, sensors,

actuators, and other electrical devices mounted on the rotor.

2. Signal and Data Transmission:

Communication Systems: They provide a pathway for transmitting signals and data between stationary and rotating parts, supporting various communication, control, and monitoring

systems integrated into the rotating equipment.

3. Rotating Sensors and Instrumentation:

Continuous Monitoring: Slip rings facilitate the connection of sensors, transducers, encoders, and other instrumentation mounted on the rotor, ensuring continuous monitoring of

parameters such as speed, temperature, vibration, and position.

4. Control and Feedback Systems:

Feedback Loops: They support the transmission of control signals and feedback data necessary for closed-loop control systems, enabling real-time adjustments and regulation of

processes occurring on the rotor.

5. Heating and Lighting Elements:

Electrical Components: In certain applications, slip rings may be used to power heating elements, lighting systems, or other electrical components mounted on the rotor, ensuring

consistent operation without the constraints of fixed wiring.

6. Industrial and Automation Equipment:

Mechanical Handling Systems: Signal Slip Rings are integral to various industrial and automation equipment such as rotating cranes, indexing tables, winding machines, and rotary joints,

where electrical connectivity is vital for their operation.

By providing a continuous electrical connection across the rotational interface, slip rings on a rotor play a critical role in facilitating uninterrupted power supply, data transmission,

sensor connectivity, and control functionality between the stationary and rotating parts of machinery, ultimately contributing to the efficient and reliable operation of rotating equipment

across a wide range of applications.

For more details on slip ring products, please view :https://www.senring.com/capsule-slip-ring/

FAQ questions:

1.How do I choose a Industrial Bus slip ring?

2.What is the current rating of a slip ring?

3.What is the purpose of electric slip ring?

4.What is the use of through bore slip ring?

5.What is capsule slip ring and is used for?

- Are Industrial Bus slip rings usually made of copper?

-

- 24-01-2024

- Yes, Industrial Bus slip rings are usually made of copper. Industrial Bus slip rings are not typically made entirely of copper. Instead, they often feature cop

- more+

- What material are Industrial Bus Slip Rings made of?

-

- 22-02-2024

- Industrial Bus Slip Rings are typically made of copper or aluminum, as these materials provide excellent electrical conductivity and durability. However, the sp

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE