What are the application fields of industrial bus slip rings?

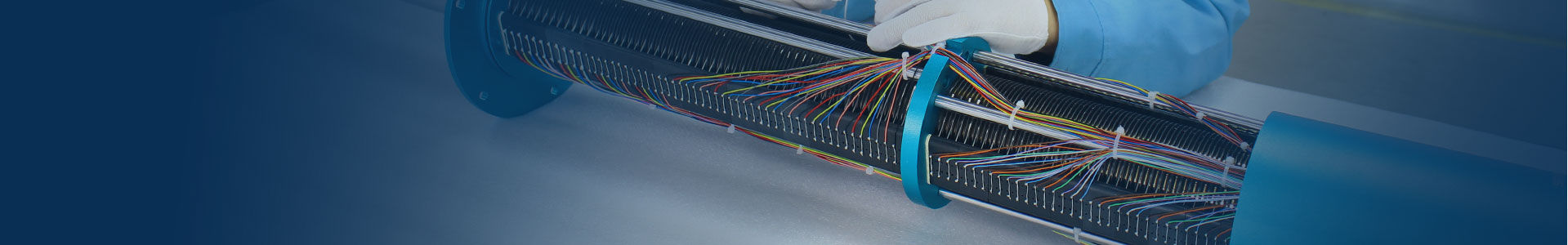

The industrial bus slip ring is an electrical component responsible for connecting and transmitting energy and signals to rotating bodies. According to the transmission medium, electric slip rings are divided into electric slip rings, fluid slip rings and smooth rings, which can also be collectively referred to as "rotating connection" or "rotating connection". Slip rings are usually installed at the rotation center of the equipment and are mainly composed of rotating and stationary parts.Slip rings are widely used. In modern high-end industrial equipment, there are many requirements for relative motion such as revolution and rotation to transmit different energy media (weak electrical signals, optical signals, air pressure, water pressure, etc.) to ensure that electrical appliances operate normally during rotation. Work. For example, common medical equipment, amusement equipment, display equipment, smart cameras, revolving doors and other equipment, as well as uncommon aerospace equipment, radar communication equipment, automatic processing equipment, smelting equipment, cable equipment, crystal furnaces

1. Industrial bus slip rings play an important role in many industrial automation and robotics applications, including but not limited to the following aspects:

Automated production lines: Industrial bus slip rings can be used for rotating equipment on automated production lines, such as rotating platforms, assembly line tools, etc., to ensure data transmission and communication connections during rotation of the equipment.

Robotic systems: Used in industrial robot arms and joint rotating parts to ensure that the robot can continuously transmit data and signals while performing tasks.

Medical equipment: Used in medical imaging equipment, such as CT scanners, MRI equipment and other equipment that require rotating scanning to support data transmission and power supply.

Aerospace field: Used in aerospace equipment that require rotating parts such as aircraft and missiles to achieve signal transmission and power transmission.

Energy industry: Can be used in wind power and solar energy equipment to support data monitoring and control of rotating blades or solar panels.

Industrial machinery and equipment: such as rotary filling equipment, rotary spraying equipment, etc., to ensure data transmission and communication.

Overall, industrial bus slip rings play an important role in many situations where rotating parts need to be maintained while maintaining data transmission and communication connections.

FAQ question:

1.What is the principle of high current conductive slip ring?

2.How does a slip ring motor transform its voltage?

3.How to fix and install pneumatic rotary joints?

4.When selecting a high-speed slip ring,what factors do you need to consider?

5.How does a conductive slip ring work?

- Are Industrial Bus slip rings usually made of copper?

-

- 24-01-2024

- Yes, Industrial Bus slip rings are usually made of copper. Industrial Bus slip rings are not typically made entirely of copper. Instead, they often feature cop

- more+

- What are the application fields of industrial bus slip rings?

-

- 11-12-2023

- The industrial bus slip ring is an electrical component responsible for connecting and transmitting energy and signals to rotating bodies. According to the tran

- more+

- What material are Industrial Bus Slip Rings made of?

-

- 22-02-2024

- Industrial Bus Slip Rings are typically made of copper or aluminum, as these materials provide excellent electrical conductivity and durability. However, the sp

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE