How to disassemble the miniature cap-type conductive slip ring?

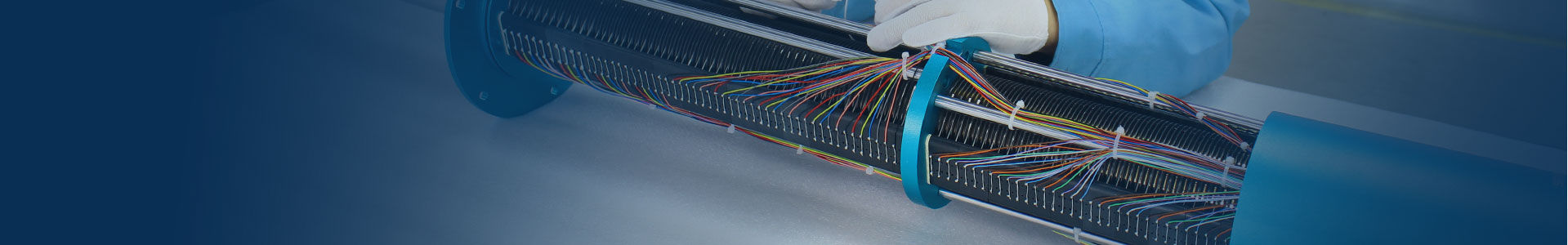

The disassembly process of the miniature cap-type conductive slip ring is relatively simple. The specific steps are as follows: first unscrew the screws on the flange, and then cut off the connecting wire. When performing these operations, special attention should be paid to the fact that the conductive slip ring is usually installed at the rotation center of the device and is mainly composed of two parts: rotating and stationary. Therefore, damage to the rotating parts should be avoided during disassembly. At the same time, since the conductive slip ring is an important component that realizes the energy and signal connection of the rotating body, the cleaning and maintenance work after disassembly should be carried out by professional maintenance personnel to ensure the stable and reliable operation of the slip ring.

1. The disassembly of miniature cap-type conductive slip rings usually requires careful operation and follow the following steps:

Confirm power is off: Before starting disassembly, make sure the power to the relevant equipment has been completely turned off and any electrical connections that may exist have been disconnected.

Disconnect external connections: If the miniature cap-type conductive slip ring is connected to other equipment (such as a robotic arm, rotary table, etc.), it needs to be disconnected from the external equipment first.

Set Screw Removal: If the miniature cap-type conductive slip ring is mounted on the equipment by set screws or nuts, first remove these set screws or nuts using an appropriate tool.

Axial disassembly: When disassembling the miniature cap-type conductive slip ring, it is necessary to adopt appropriate methods to gradually disassemble it along the axial direction according to the specific design. This may require tapping or using a special removal tool.

Check the connecting wires: If the conductive slip ring has connecting wires, be sure to handle them carefully during disassembly to avoid damaging the connecting wires.

Record Details: During disassembly, record any important details, such as the order of disassembly and how components are laid out and connected to each other. This will help when reinstalling.

Cleaning and maintenance: After the miniature cap-type rotary electrical slip rings is disassembled, it can be cleaned and maintained, including removing dust, lubricating the contact parts, etc.

Please note that since the miniature cap-type conductive slip ring is a precision device, care must be taken when disassembling it to avoid damaging key components. It's best to consult the relevant product manual or manufacturer for model-specific disassembly guidance before disassembly.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE