What are the technical standards for large-diameter conductive slip rings?

What are the technical standards for large-diameter conductive slip rings?1. What is a conductive slip ring?

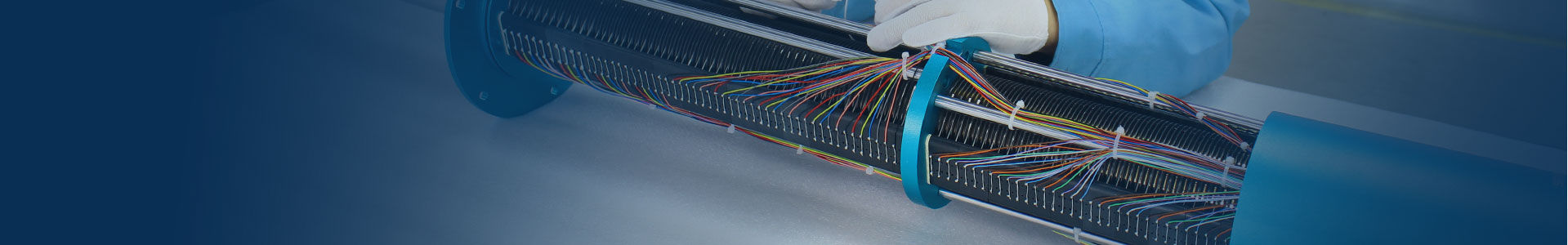

A rotary electrical connector is a component that provides a sliding connection. It is mainly used to realize the connection device of analog or digital signals and power transmission between two relative rotating mechanisms. Conductive slip rings have the advantages of safety, reliability, stability, low temperature resistance, maintenance-free and extended service life. The main components of a conductive slip ring include elastic materials - brushes, sliding contact surface materials - conductive rings, insulating materials, bonding materials, combination brackets, precision bearings, dust covers and other auxiliary parts.

A conductive slip ring is a rotating connection device used to transmit electrical energy or signals. It is usually used in equipment that requires rotating parts.

2. What aspects do the technical standards of large-aperture conductive slip rings usually include?

a. Working speed during rotation;

b. Circuit channels and signal channels;

c. Maximum voltage and maximum current of power circuit and signal circuit;

d. The type of signal, this is very important;

e. Working temperature;

f. Protection level, that is, sealing requirements.

g. Electrical performance: including rated voltage, rated current, insulation resistance, conduction resistance and other parameters;

h. Mechanical properties: including maximum speed, load-bearing capacity, working life and other parameters;

i. Environmental adaptability: including high temperature resistance, corrosion resistance, dustproof and waterproof, etc.;

j. Safety performance: including fire and explosion-proof performance, grounding protection, etc.;

k. Appearance requirements: including overall dimensions, surface treatment, installation method, etc.

Conductive slip rings can be classified according to their overall structure and design, such as through-hole conductive slip rings, cap-type conductive slip rings, miniature conductive slip rings, insert-type conductive slip rings, hollow shaft conductive slip rings, and separated conductive slip rings. , disc type conductive slip ring, wind power conductive slip ring, optical fiber conductive slip ring, high frequency conductive slip ring, mercury conductive slip ring, etc. According to the performance of conductive slip rings, they can be subdivided into high-speed slip rings, high-temperature conductive slip rings, wind power slip rings, thermocouple slip rings, high-current slip rings, explosion-proof conductive slip rings, military-grade electric slip rings, and waterproof slip rings. Slip rings, HD conductive slip rings, USB slip rings, etc.

In general, the formulation and promotion of conductive slip ring standards are very important to ensure the normal operation and maintenance of equipment. With the emergence of new technologies and market demands, existing standards need to be continuously improved and updated to adapt to new changes, thereby promoting the steady development of the conductive slip ring industry.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE