How to wire a Pneumatic Rotary Union & Rotary Joint?

The gas-electric slip ring, also known as the Pneumatic Rotary Union & Rotary Joint, is a conductive ventilation and conductive device that can rotate 360° without restriction. It is particularly widely used in industrial automation turntables, especially where cylinders, suction cups, solenoid valves and sensors are required.Regarding the wiring method of gas-electric slip rings, the following are some key points:

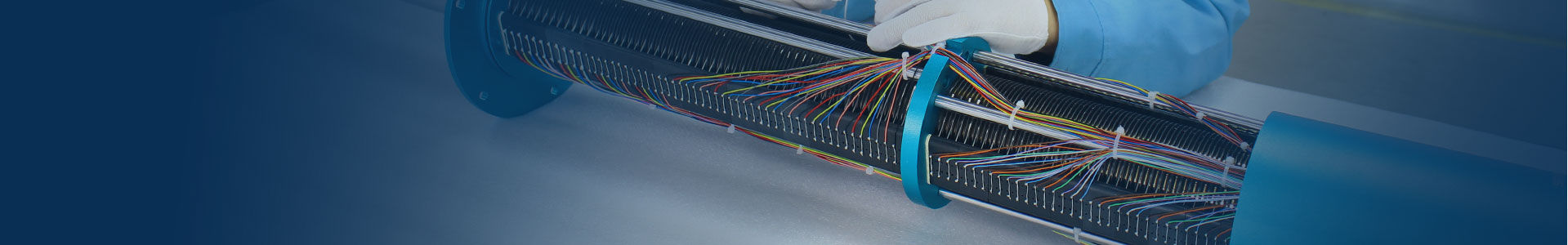

Through-hole slip ring wiring: This wiring method is to lead wires from both ends of the slip ring and the end face of the rotor central shaft. If the number of channels is very large, there will be two or three oval outlet holes. The outlet wire at the stator end is usually led out from the end face of the side, usually 1 to 2 oval outlet holes.

Installation Precautions:

In places with severe vibration, it is recommended to add spring washers to ensure that the screws will not loosen.

There are two anti-rotation holes on the outside of the slip ring body. When the anti-rotation rod is tightened into the anti-rotation hole, the connection between the anti-rotation rod and the stator part should maintain a certain degree of freedom, otherwise the slip ring may be damaged.

When installing a slip ring, be sure to protect the wires to avoid damage to the insulation layer of the wires, which may affect the quality of the product.

If the installation location does not match the flange location of the slip ring, a transition flange may be required. In addition, the mounting position of the flange is a toothed hole, which requires special attention.

In short, the wiring and installation of gas-electric slip rings require careful and professional skills to ensure their normal operation and extend their service life.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE