How to install and use pneumatic rotary joints and rotary joints?

Pneumatic rotary joints and rotary joints are devices used to transmit gas media and rotation signals. They are commonly used in industrial automation, fluid control and other fields. Here's how they are generally used:1.Installation location:

Determine the installation location of the pneumatic swivel joint or swivel joint, and ensure that it is properly connected to the relevant equipment or pipes.

2.Connection method:

According to the specific model and requirements, select the appropriate connection method, usually threaded connection, flange connection, quick connector, etc.

3.Connect the pipe:

Connect the pneumatic rotary joint or swivel joint to the corresponding gas pipe. Make sure the connections are tight and well sealed to avoid gas leakage.

4.Control the gas supply:

Control the supply and stop of gas through external control devices such as valves or pneumatic control systems. Adjust gas pressure and flow as needed and ensure stable gas supply.

5.Test run:

After the installation is completed, conduct a test run to ensure that the rotary union pneumatic or rotary joint can smoothly transmit the gas medium and rotation signal, and check whether there are any abnormalities or problems.

Please note that the above are just general usage methods, and the specific operation steps may vary depending on product models, installation environments, etc. Before installation and use, please be sure to refer to the instructions and operating guides of the relevant products or seek professional advice.

When installing and using pneumatic rotary joints and rotary joints, you need to follow the following steps and precautions:

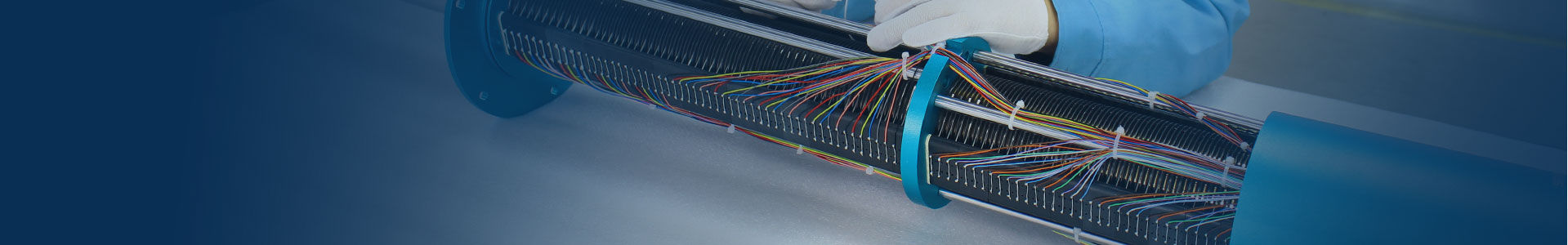

First of all, make sure the rotary joint drum and the inside of the pipe are clean before installation to prevent wear of the rotary joint caused by foreign matter. Filters can be added according to usage requirements. At the same time, it ensures the reliability of the rotary joint bearing operation and prevents damage or deformation of components caused by impact and impact. In addition, care must be taken during installation and maintenance to avoid overloading or disassembly.

Secondly, hoses should be selected to connect to the machine during installation to reduce auxiliary weight and vibration, thereby effectively extending the service life of the rotary joint. For threaded rotary joints, attention should be paid to whether the thread direction of the inner and outer tubes corresponds to the rotation direction of the roller, and the thread direction of the inner and outer tubes should also be consistent.

Then, pay attention to the assembly of the inner tube, the matching of dimensions and the auxiliary support of the weight are very important. It is recommended to use the H8/e7 tolerance standard for the inner tube and joint of the inner tube rotary joint. In order to enable automatic adjustment and compensation when the rotary joint is used, it is recommended that the support and anti-rotation of the rotary joint should be coordinated. Generally, the diameter of the rod should be 2mm smaller than the anti-rotation hole.

Finally, during use, the rotary joint should be used correctly according to the requirements of the installation and operation instructions, otherwise its sealing performance and lifespan will not be fully exerted. At the same time, it should be noted that the mixing of fluids, gases, dielectrics, etc. is converted into a dynamic state through the pneumatic and electrical integrated rotary joint.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE