Notes for the slip ring packaging and application in packaging machine

There are a lot of packaging skills and notes in slip ring express, it will easily bring many disputes if we don`t pay attention on them. In the previous text, as a slip ring manufacturer, we`ve discussed the notes and how to select a logistic company. Next, we`ll make a full introduction of the packaging skills for each series of product based on Senring past experience. At the same time, it will explain the company product quality and high responsibility attitude to customers with examples. And hope this responsible attitude towards express will be carried through each area of company in the future.

In general, many customers of Senring distribute around the country, the farthest in Heilongjiang Province and Xinjiang Province, so many products are needed to be arrived on time and safety. In the development of Senring, almost never occurred delivery delay by the collision and friction quality from logistics. All of these are ensured by rules and regulations as well as details.

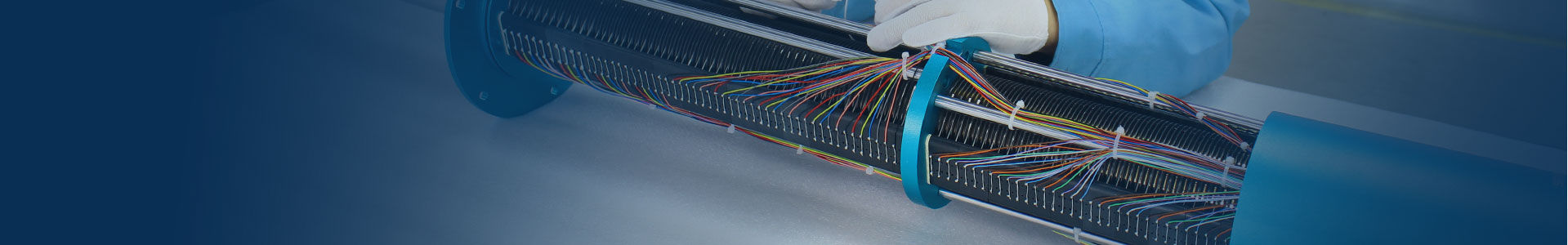

We should determine the type of logistics before delivery, such as railway, truck or plane, and make different levels of packaging according to the various types. There are different packing types according to the type of product. For example, through hole slip ring, capsule slip ring, high-frequency slip ring and optoelectronic slip ring have different levels of security in packaging. The most common is three-layer distributed package because one slip ring has three packaging level. Firstly, the outer layer of each one is a plastic bubble pouch which protects the friction between slip rings and external force transfer, and then it will have no problem even the whole box extruded. Then, five slip rings packed into a big plastic bubble pouch which avoiding the individual loose. Finally, several big plastic bubble pouches will be used foams to separate and packed into a box. So it will avoid the collision and ensure the safety in transportation.

For Senring, it cares not only the details on slip ring logistics, but also the strict quality which is a key for an enterprise to survive. Or in other word, good quality will save the potential re-work and re-deliver cost, actually it saves the cost, too. Only we do well the details in the slip ring express packaging skills, the quality can be more perfect. Besides the express cost, the most important factors are reputation, service and the cooperation and so on.

- Application for slip ring rotating parts in packaging machine

-

- 28-05-2011

- The robot and automation equipment are often used in packaging machine, especially in the rotating joint parts. This industry is also the one which the slip rin

- more+

- Notes for the slip ring packaging and application in packaging machine

-

- 14-09-2011

- There are a lot of packaging skills and notes in slip ring express, it will easily bring many disputes if we don`t pay attention on them. In the previous text,

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE