Slip rings come in a lot of different shapes and sizes. Is there a performance difference between pa

Although we've designed some excellent pancake slip rings, our expertise has shown that a drum design is more cost effective and performs better than a pancake design. A pancake slip ring usually has: greater weight and volume for the same circuits, greater capacitance and crosstalk, greater brush wear and more readily collects wear debris on its vertical axis. However, a pancake offers reduced axial length for the number of circuits. So the decision to use a pancake is usually due to the size and shape of the envelope with which you're work.

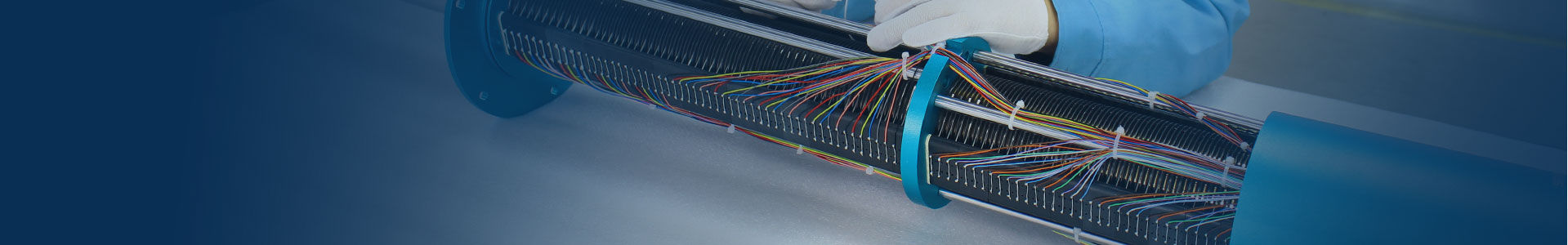

SenRing is a worldwide designer, manufacturer of precision slip rings products and rotary joints systems devoting ourselves to research,testing,production. and sales. we have established long-term business relations with well-know enterprises including military industry, research institution and university from all over the world. Our products is consist of high-end, middle end and low end, the special slip ring, such as carbon brush, electrical slip ring and electrical rotary joint and so on.

- What are the limitations of Pancake Slip Rings?

-

- 05-02-2024

- The limitations of Pancake Slip Rings include: Limited space for components, which can restrict the number of circuits and capabilities. Reduced ability to ha

- more+

- What is Pancake Slip Rings?

-

- 06-03-2024

- Pancake slip rings, also known as flat slip rings, are specialized electrical devices used to transmit power, electrical signals, or data across rotating interf

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE