Introduction

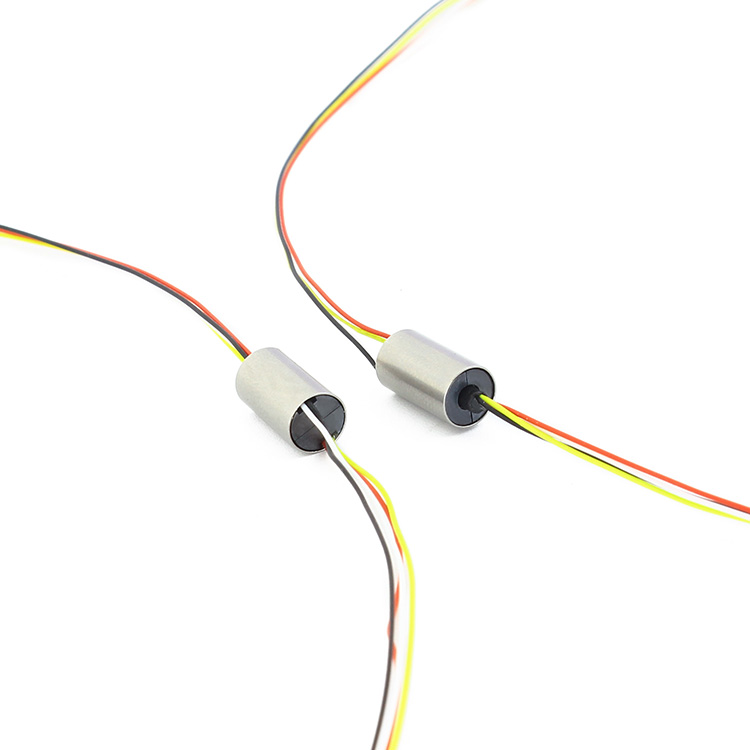

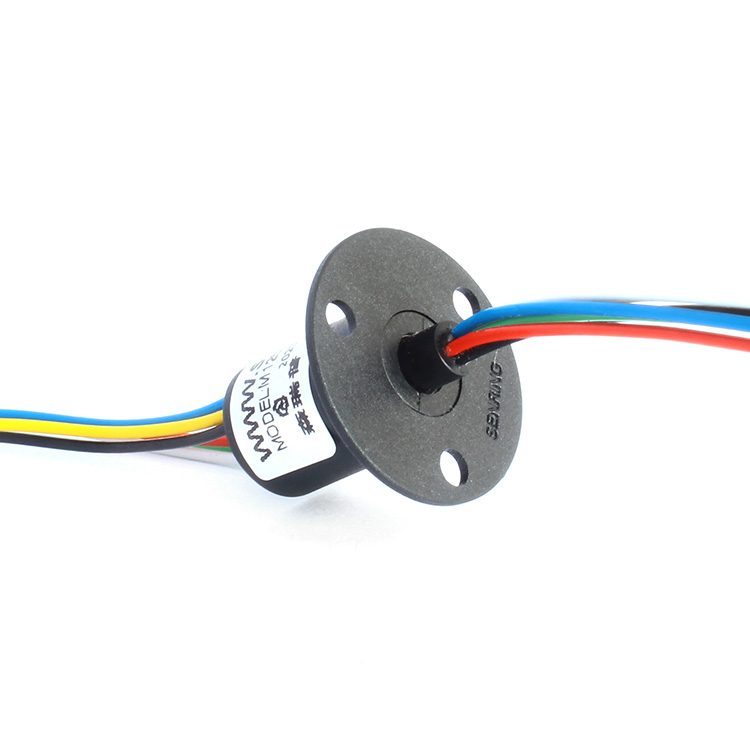

The colossal furnaces and relentless machinery of metal production rely on a seamless flow of power, data, and fluids. But behind the scenes, a lesser-known technology plays a critical role in keeping this industry moving: slip rings and rotary unions. These seemingly simple devices address a fundamental challenge – enabling uninterrupted transmission within equipment featuring rotating components.

Ensuring Continuous Operation in Metal Processing

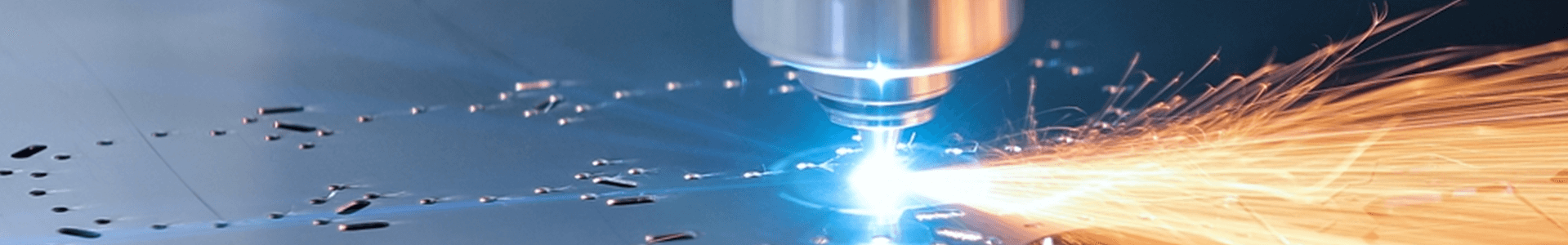

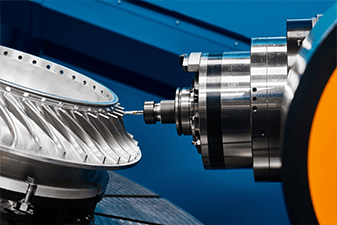

Metal processing equipment like coilers, coiling machines, and continuous casting lines utilize rotating components for functions like unwinding, winding, and shaping molten metal. Traditional wiring methods for these machines become entangled and restrict movement, hindering efficiency and potentially causing damage.

Slip rings and rotary unions offer a reliable solution! Slip rings transfer electrical signals and control data, while rotary unions handle fluids (coolants, hydraulics) – all while a component rotates freely. This ensures smooth operation and maximizes production output.

Diverse Applications in Metal Manufacturing

The benefits of slip rings and rotary unions extend across various metal production applications:

Coiling Lines: Facilitate continuous power and control signal transfer to the rotating mandrel for efficient unwinding and coiling of metal sheets.

Continuous Casting Lines: Ensure uninterrupted flow of data and control signals between the static control unit and the rotating mould for precise shaping of molten metal.

Welding Machines: Enable seamless power and control signal transfer to the rotating welding head for automated and efficient welding processes.

Key Considerations for Metal Production Applications

High Durability: Metal production environments are harsh. Senring high-speed, high-temperature slip rings and rotary unions are built with robust materials and rigorous testing to withstand extreme temperatures, vibrations, and heavy loads.

High Current Capacity: Metal processing often demands significant power. Senring high current slip rings offer high current capacity to handle the power requirements of this machinery.

Corrosion Resistance: Metal production processes involve coolants and lubricants that can cause corrosion. Senring F-Series, dustproof and waterproof slip rings are built with corrosion-resistant materials to ensure long-term operation.

Powering Efficiency in Metal Production

In the demanding world of metal production, maximizing uptime and ensuring efficient operation are paramount. Senring continues to innovate in providing high-performance 360° slip rings and rotary solutions, specifically designed to meet the rigorous demands of metal production applications.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE