Introduction

Ensuring consistent quality and hygiene are paramount concerns in the food and beverage industry. But behind the scenes, a lesser-known technology plays a critical role in keeping production lines running smoothly: slip rings and rotary unions. These seemingly simple devices address a fundamental challenge – enabling uninterrupted flow of power, data, and fluids in equipment with rotating components.

Ensuring Continuous Operation in Food & Beverage Processing

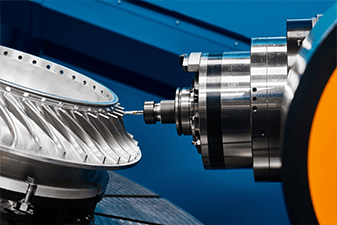

Modern food and beverage processing relies on a variety of equipment with rotating elements, such as bottling machines, mixers, and filling lines. Traditional wiring schemes for these machines can snag or break during operation, leading to costly downtime and potential contamination risks.

Slip rings and rotary unions offer a reliable solution! Slip rings transfer electrical signals and data, while rotary unions handle fluids (water, air, lubricants) – all while a component rotates freely. This ensures uninterrupted operation and maintains consistent product quality.

Diverse Applications in Automated Manufacturing

The benefits of slip rings and rotary unions extend across various food and beverage production processes:

Bottling Lines: Facilitate continuous power and control signal transfer to labelling and capping machines with rotating turrets.

Mixing Equipment: Ensure uninterrupted flow of ingredients and control signals in mixers with rotating agitators.

Filling Lines: Enable seamless data and power transfer on equipment with rotating filling heads, ensuring accurate and consistent product dispensing.

Key Considerations for Food & Beverage Applications

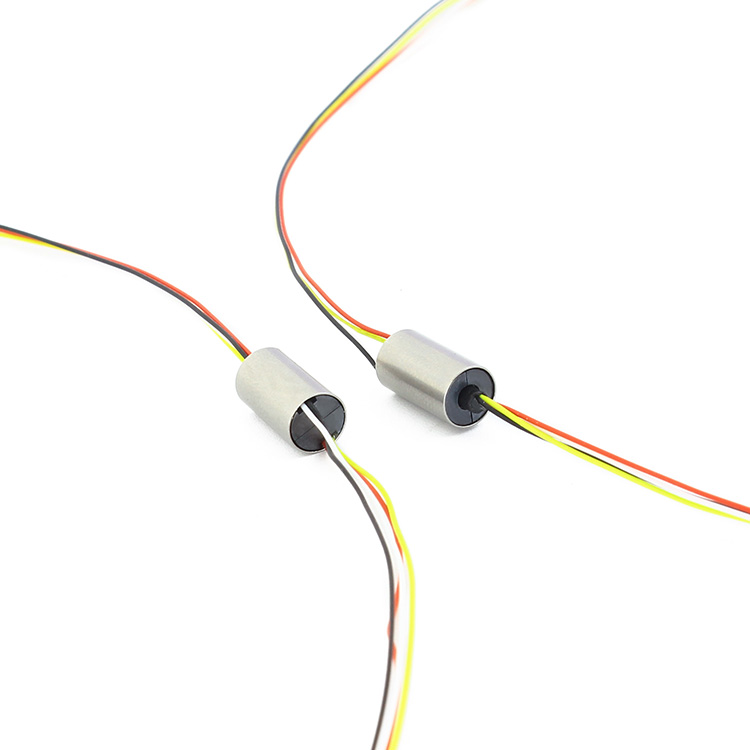

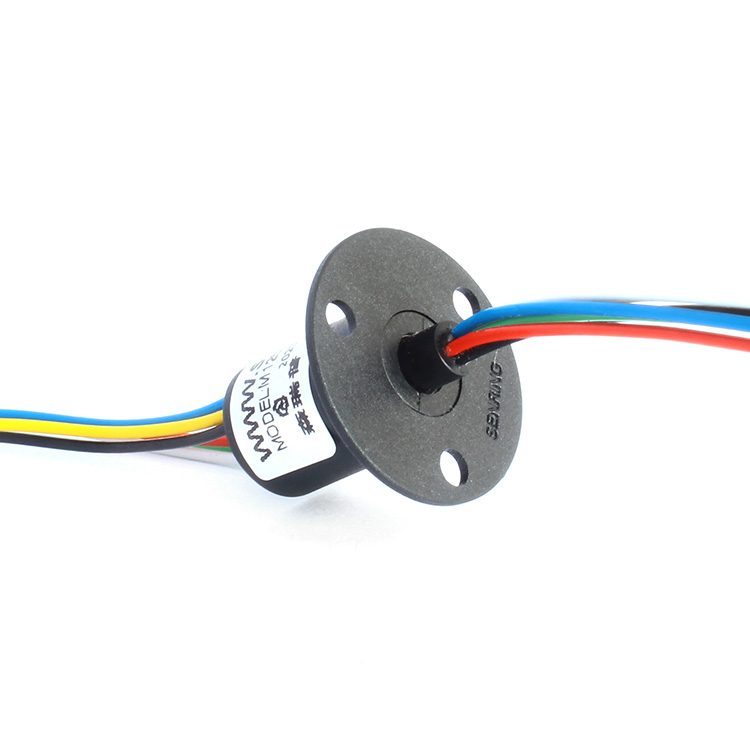

Hygiene Standards: Food safety is paramount! Senring F-Series slip rings are built with food-grade materials and meet strict hygiene standards to prevent contamination risks.

Corrosion Resistance: Food and beverage production environments can be harsh. Senring signal slip ring and rotary unions solutions are corrosion-resistant to withstand cleaning chemicals and moisture exposure.

Washdown Compatibility: Frequent washdowns are essential for maintaining hygiene. Senring offers washdown-compatible slip rings and rotary unions that can endure high-pressure cleaning processes.

A Recipe for Success in Food & Beverage Production

In the fast-paced world of food and beverage manufacturing, efficiency and hygiene are crucial. Slip rings and rotary unions, by enabling seamless connectivity in rotating equipment, contribute significantly to a successful recipe. Senring, a global leader with over 11 years of specialized experience, continues to innovate in providing high-performance 360° slip rings and rotary solutions that meet the demanding requirements of the food and beverage industry.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE